-->

江苏省溧阳欣宇机械厂是专业生产各种起重机整机、港口机械配件为主的生产企业,主要产品和服务有各种起重机械配件及起重机械的安装,及自主研发的MA型电缆分切加工中心。

-->

江苏省溧阳欣宇机械厂是专业生产各种起重机整机、港口机械配件为主的生产企业,主要产品和服务有各种起重机械配件及起重机械的安装,及自主研发的MA型电缆分切加工中心。

-->

-->

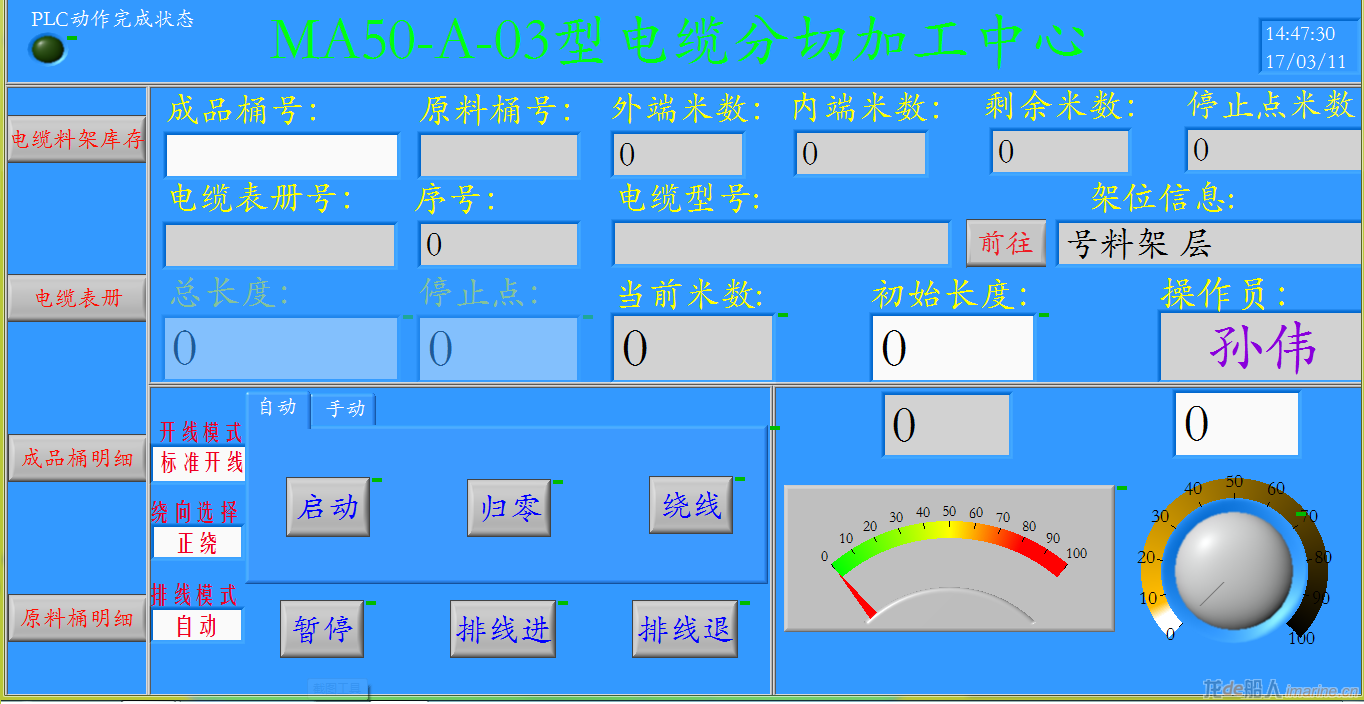

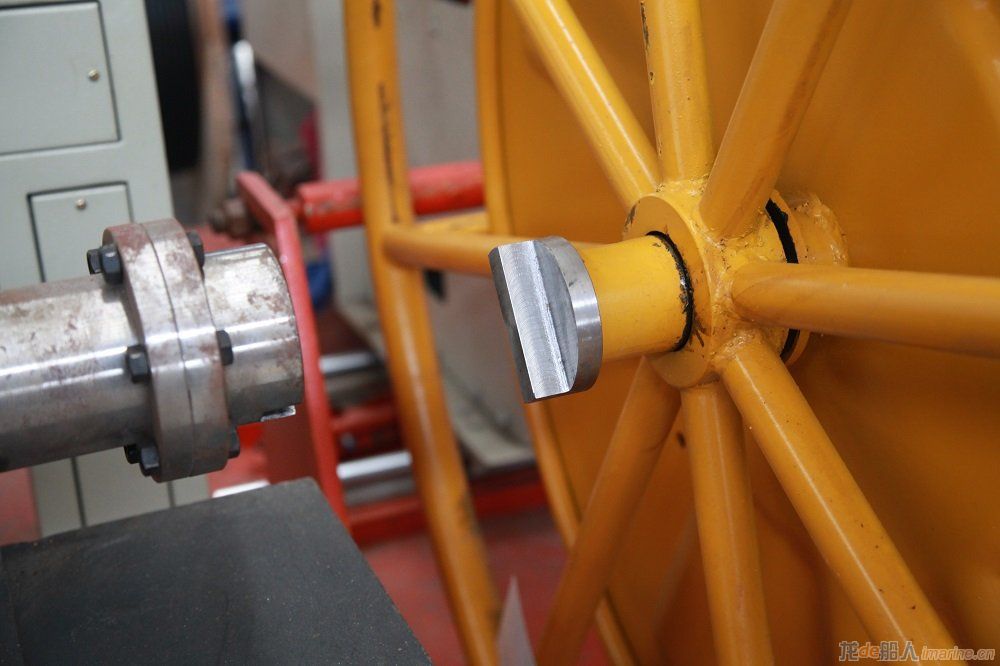

Jiangsu LiyangXinyu Machinery Plant is a manufacturing enterprise specializing in themanufacturing of all kinds of chain blocks and accessories for port handlingdevices. Its major products and services include all kinds of accessories forchain blocks and installation of hoisting machinery, as well as theself-developed MA series Cable Cutting and Processing Center. 电缆分切加工中心是适合大型线缆加工企业、大型船厂分切卷绕电缆的理想设备。该设备改变了传统的机械传动及计数计米的工作模式,采用了先进的液压泵站,集中供油,湿式电磁换向阀来控制泵站供油,以达到对油缸工作速度的调节,使设备运行平稳、可靠。控制系统采用先进的PLC、人机界面系统,操作、设置界面更人性化。计米装置选用高精度的旋转光电编码器配以压力式旋转机构,使计米精度大大提高。线缆卷绕采用先进的变频调速技术,可根据线径大小选择适当的卷绕速度,设备卷绕启动和停止时更平稳,无冲击。 The Cable Cutting and Processing Center is theideal equipment that suitable for large-scaled cable/wire machiningenterprises, large-scaled shipyard to cut and convolute cables. It haschallenged the traditional mechanical transmission meter counting method. Thecenter uses advanced hydraulic pump station, central oil supply and wetelectromagnetic directional valves to control the oil supply, which enablesadjusting of cylinders' operating speed, allows the device to operate smoothlyand reliably. The use of (Programmable Logic Controller) PLC, human-computerinterface in controlling system makes the operating and setting interfacefriendlier. The high-accuracy circumrotatephotoelectric encoder together with pressure circumrotate structure are used inthe meter counting device, which greatly improves the meter-counting precision.Further, the advanced frequency variation speed control technology is used toconvolute wire/cable, which allows choosing appropriate convoluting speed basedon the wire/cable's diameter. Therefore, the device can start up and stop moresmoothly, and avoid concussion.

-->

-->

MA50-A-03型电缆分切加工中心 Cable Cutting and Processing Center Model MA50-A-03MA50-A-03型电缆分切加工中心是我公司在2016年最新研发的新一代产品,继承了MA50-A-01型的所有机械化优点,采用的工业控制系统可以实现电缆分切加工的多元化操作。我们致力于打造全球最专业的电缆分切加工设备,并提倡最科学的生产管理模式,在降低成本的同时,提高生产效率,提升成品质量。所以本产品一经上市,得到使用单位的一致好评。我们也将不断拓展和提高产品功能、性能,让我们的产品更趋完美。 MA50-A-03 Cable Cutting and Processing Centre is the latest model we developed in 2016. This new generationproduct has inherited and improved all the mechanical advantages. The use of IndustrialControl System enables diversified operations when cutting and processcable/wire. We have devoted ourselves to create the most professionalcable/wire cutting and process equipment. We advocate the most scientificproduction management mode, to improve production efficiency while reducingcost, and improve product quality at the same time. Therefore, the new modelhas won itself praise from end users. In the meantime, we won’t stop perfectour product by developing new functions and improving performances. MA50-A-03型电缆分切加工中心优化了电缆分切加工模式,不断提高工作效率,设备最高卷绕速度达到99米/分。按每天实际绕卷4小时,实际速度60米/分计算,每天卷绕工作量便可达到15千米左右。按一艘中型船每条船的加工量为400-500千米,使用MA50-A-03型电缆分切加工中心只需3个月就可以完成所有电缆的分切加工工作。节省大量工时及运转周期,最多半年就可以收回设备投资成本。

-->

-->

cutting and processing model, keepimproving working efficiency. The maximum convoluting speed has reached99m/min. Calculating practically by 4hours per day of actual working time, practical convoluting speed 60m/min,approximately 15,000 meters of cable/wire can be convoluted per day. Take amedium sized vessel for example, 400-500 km of cable/wire need to be processed,which takes less than 3 months to finish all the work. By saving large numberof working hours, and shorten running period, the MA50-A-03 CableCutting and Processing Centre usually pay for itself in less than half a year. 新研发的操作系统采用LabVIEW;OPCSERVERS;SQLSERVER;等功能强大的软件,控制PLC完成动作,记录工作内容。添加了自动寻线搜索,生产任务导入,原料使用,配盘管理等功能。 The newly developed operating system has adoptedLabView, OPCSERVERS, SQLSERVER to control the PLC (Programmable LogicController), and record working data. The newly added functions include automaticcable searching, production task importing, material usage recording, reedmanagement etc.

-->

-->

物流管理功能,可准确记录原料位置,打开生产任务时,只需一点,便可轻松找到目标线盘位置。显著提高了切线工作的工作效率。并可将所有原料使用情况全部记录、导出,使现场管理更简便,更精确。物流数据更准确。 Thelogistic management function keeps records of all material locations, which improvesworking efficiency. Once open a production task, the location of target reed isjust one click away. All records can be outputted to Excel files, allows easyand precise onsite management. The new operating system usesEXCEL file for importing and outputting, makes processing production data eveneasier.

-->

-->

操作系统导入与导出的表格采用办公通用软件EXCEL格式,使您轻松完成生产数据的处理,对原料使用及成品数据做到科学管理。我公司多年来一直承接沪东中华船厂的电缆加工业务,已逐步形成了一套完整的电缆分切加工管理体系,从原料购置方案、生产任务评估,到切线方案确定、仓储物流管理,直到成品交付使用。努力做到数字化管理,避免余料产生。望与全国各业内人士学习交流,不断完善。 We have been carrying on Hudong-ZhonghuaShipbuilding’s cable/wire processing work for many years. With plenty ofexperiences, we have developed a complete cable/wire cutting and processmanagement system, which consists material purchase scheme, production taskassessment, cutting scheme determination, warehouse logistic management, andfinal product delivery. Excess material is kept to minimum by digitalmanagement. We would love to communicate and 电缆分切加工中心优势 Advantagesof Cable Cutting and Processing Center1:整车行走寻线,机动灵活。 Whole centermoves on the pre-installed rail, highly flexible. 2:机械化进线,省时省力。 Mechanizedcoil in, saves time and effort. 3:变频绕线,更精确,更安全。 Frequency variation speed control convoluting, improved precision andsafety. 4:可控手/自动排线,绕线更平整。 Controllable manual/automatic winding, neater rolls. 5: 360度进线滚轴,线缆零损伤。 360 degree coil in roller, no damage to cable/wire. 6:高精度编码器,计米更精确。 High-accuracy encoder, improved metercounting accuracy. 7:液压剪刀嵌入式安装,切割更方便 Integrated hydraulic scissor for more convenient cutting. 8:工控系统触屏操作,更先进。 Touch screen project control system, more convenient and intuitiveoperation 9:数据处理系统,物流数据更透明。 Dataprocess system, clearer logistic data. 10:软件功能强大,操作简单。 Powerful functions,yet simple operations. 我公司出品的线缆料架及绕线专用盘可按现场实际生产情况量身定制!客户的要求,就是我们努力的目标!

-->

-->

-->

-->

Our Cable Rack and Cable Roll Reed can be customizedbased on customer’s actual needs. Customers’ requirements are our tragets! 十几年来,我公司生产的线缆切割机已日趋成熟,产品发往大江南北。我公司拥有专业的设备维护团队,为广大用户提供最优质的售后服务 During last decade, our Cable Cutting andProcess Centre has become a mature product, and sold nationwide. Ourprofessional maintenance team will provide the best after sale services. Anyissue arises will be our first priority to research and solve as soon aspossible. 溧阳欣宇机械厂竭诚为您服务! Liyang Xinyu Machinery Plant, wholeheartedly at yourservice! 关注微信公众号及公司网站获得更多资讯: 项目负责人: 孙 伟 13918799409 Project Manager: Sun Wei |